AI in Manufacturing: Uses, Examples, Benefits & Future in 2026

Artificial Intelligence is redefining the manufacturing industry by enabling smarter production, predictive maintenance, and data-driven decision-making. As factories become more connected, AI is emerging as a core driver of productivity and efficiency.

From shop-floor automation to supply chain optimization, AI in manufacturing is transforming how products are designed, produced, and delivered at scale.

What Is AI in Manufacturing?

AI in manufacturing refers to the application of artificial intelligence technologies to improve production processes, quality control, maintenance, and supply chain operations.

AI systems analyze large volumes of machine data, sensor inputs, production logs, and historical records to identify patterns that are difficult for humans to detect. This enables manufacturers to move from reactive operations to predictive and autonomous systems.

Unlike traditional automation, AI-driven manufacturing systems continuously learn and adapt, making them suitable for complex, high-variability production environments.

How Is AI Used in Manufacturing?

AI is used across the manufacturing value chain, from design and planning to production and post-sales support.

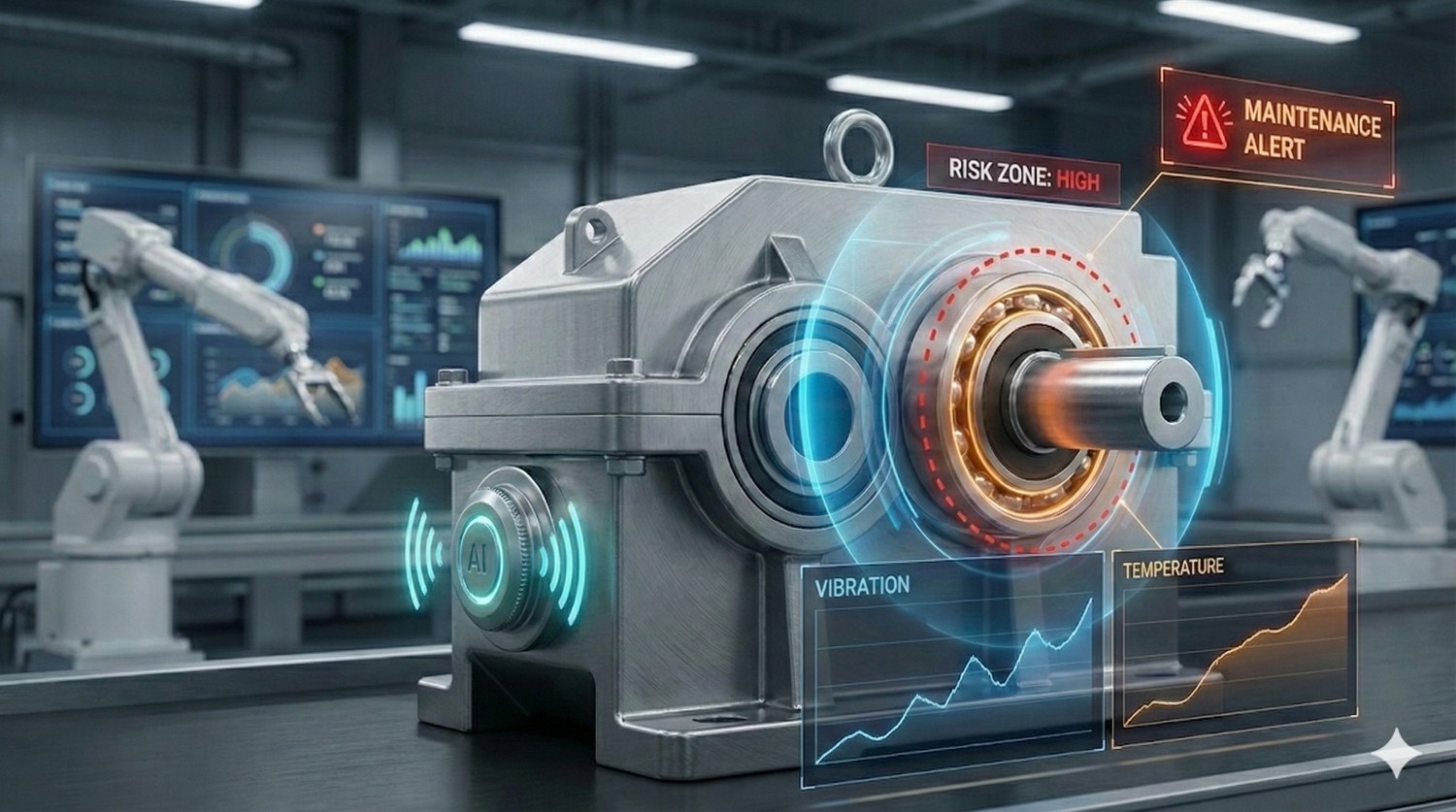

- Predictive maintenance of machinery

- AI-driven quality inspection and defect detection

- Production planning and demand forecasting

- Robotics and intelligent automation

- Supply chain and inventory optimization

AI in Manufacturing Use Cases

Manufacturers use AI-powered computer vision systems to inspect products at high speed and accuracy, reducing defects and waste. Predictive maintenance models analyze sensor data to anticipate equipment failures before breakdowns occur.

AI is also applied in process optimization, where machine learning models continuously adjust parameters to improve yield, energy efficiency, and throughput.

Benefits of AI in Manufacturing

| Benefit | Impact |

|---|---|

| Higher Productivity | Optimizes production output and efficiency |

| Reduced Downtime | Prevents unexpected equipment failures |

| Improved Quality | Detects defects with high accuracy |

| Cost Optimization | Reduces waste and operational costs |

| Supply Chain Resilience | Improves forecasting and inventory control |

Challenges of AI in Manufacturing

Despite its benefits, adopting AI in manufacturing comes with challenges such as high implementation costs, data quality issues, integration with legacy systems, and workforce skill gaps.

Successful adoption requires strong data infrastructure, cross-functional collaboration, and continuous workforce upskilling.

Future of AI in Manufacturing

The future of manufacturing lies in autonomous factories where AI systems coordinate production, maintenance, and logistics with minimal human intervention.

By 2026 and beyond, AI-driven manufacturing will play a central role in smart factories, sustainable production, and global supply chain competitiveness.

Frequently Asked Questions

How is AI used in manufacturing?AI is used for predictive maintenance, quality inspection, automation, and supply chain optimization.

Which companies use AI in manufacturing?Many global manufacturers use AI to improve productivity and quality across operations.

Will AI replace manufacturing jobs?AI will change job roles but also create demand for skilled technical professionals.

© 2026. All rights reserved.